Key Takeaways

|

Table of Contents

Clean beer lines are the foundation of great-tasting draft beer—and without consistent commercial beer line cleaning, businesses risk serving off-flavors, wasting product, and damaging expensive equipment. In the world of draft beer, quality doesn’t happen by accident. It’s achieved through routine maintenance, attention to detail, and a commitment to cleanliness.

Over the past year, industry reports have highlighted a growing focus on stricter draft-system hygiene, with organizations like the Brewers Association (BA) emphasizing more frequent cleanings and improved technician training. As a result, many bars and restaurants nationwide are reevaluating their cleaning schedules — some shifting from biweekly to weekly service to stay ahead of buildup and flavor issues.

For bars, restaurants, breweries, and entertainment venues in Putnam County, proper commercial beer line cleaning is what separates a “good enough” pour from a flawless one customers return for.

When beer travels through lines that aren’t regularly cleaned, buildup forms, flavors degrade, and efficiency drops—costing businesses money and reputation. This is why understanding the cleaning process and partnering with trained professionals is essential for any business relying on a dependable draft system.

What Is Commercial Beer Line Cleaning and Why It Matters for Draft Quality

Commercial beer line cleaning is the routine process of removing yeast, mold, bacteria, and beer stone from draft lines to maintain a clean, unobstructed path for beer to flow. Beer is a perishable product, and as it sits in lines, residue naturally forms. Without consistent cleaning, this residue becomes a breeding ground for spoilage organisms and biofilm.

A well-maintained draft system produces clean, consistent flavors, maintains carbonation, and ensures the beer tastes exactly as the brewer intended. For businesses, this directly impacts customer satisfaction, product integrity, and revenue. Clean lines protect your investment in your draft equipment and reduce long-term operating costs.

How Dirty Beer Lines Affect Flavor, Consistency, and Customer Satisfaction

Flavor inconsistency is one of the biggest red flags for customers. Dirty beer lines create noticeable off-flavors—sourness, butteriness, metallic tastes, vinegar notes, and aroma issues. These flaws are often misattributed to the brewery, but in reality, they result from contamination inside the draft lines.

Beyond taste, dirty lines cause foaming problems and unstable pours, which lead to wasted beer and higher costs. Excess foam makes staff slower and less efficient, and customers quickly lose confidence in a bar or restaurant that can’t pour a proper pint.

Clean lines aren’t optional—they are central to a reliable, profitable draft program.

Quick Facts: Why Clean Beer Lines Matter

- Flavor degradation can occur in as little as two weeks without cleaning.

- Beer stone buildup hardens and becomes harder to remove over time.

- Foaming issues often come from dirty or narrowed lines.

- Biofilm can harbor harmful microorganisms.

- A clean system reduces beer waste and increases profitability.

Essential Cleaning Process for Professional Draft System Maintenance

Step 1 – Flush the Beer From the Lines With Clean Water

The cleaning process begins by running water through the beer lines to remove any remaining beer. This prevents cleaning chemicals from being diluted, allowing them to work at full strength. Trained technicians flush until the water runs clear, ensuring the line is fully primed for chemical cleaning.

Step 2 – Clean the Lines With the Appropriate Chemical Solution

Once the lines are cleared, an industry-approved cleaning solution is circulated or allowed to soak in the lines for at least ten minutes. This step is critical for breaking down beer stone, organic matter, and biofilm.

Proper mix ratios, water temperature, and manufacturer specifications are essential to ensure the chemicals work safely and effectively. This deep-cleaning stage removes buildup that normal rinsing can’t reach.

Step 3 – Flush the Lines Again and Verify System Safety

After the chemicals have completed their job, the lines are thoroughly flushed with clean water to remove all residue. Technicians then use pH testing tools to ensure no cleaner remains. Finally, kegs are reconnected, beer is run through the faucet, and the initial pour is discarded to guarantee the system is completely refreshed with clean, untarnished beer.

How Routine Draft System Cleaning Improves Equipment Longevity and Efficiency

A neglected draft system doesn’t just harm beer quality—it strains equipment. Buildup inside lines causes resistance, altering temperature and pressure balance. This results in premature wear on pumps, couplers, gaskets, and faucets. Regular cleaning minimizes these issues, reduces the frequency of mechanical failures, and helps maintain consistent performance.

Clean lines also ensure accurate carbonation and flow rates, which reduces foaming and waste. When the system operates efficiently, businesses save time, product, and money.

Cleaning Frequency: How Often Businesses Should Clean Their Commercial Draft Lines

Industry experts and breweries recommend cleaning beer lines every two weeks. High-volume bars may require more frequent service, especially when serving sensitive craft beers. Seasonal tap changes, events, or long periods of downtime also impact cleaning needs.

Warning signs your lines need attention include unusual flavors, persistent foaming, slow pours, and cloudy beer. Regular maintenance protects your investment and aligns with industry-recommended standards.

Professional vs. In-House Draft Line Cleaning: What Businesses Should Know

Advantages of Hiring Commercial Beer Line Cleaning Experts

Hiring trained professionals for commercial beer line cleaning ensures your draft system receives the level of care, precision, and consistency needed to maintain peak performance. From advanced equipment to expert handling, professional services offer critical advantages that protect both beer quality and long-term system health.

Commercial-Grade Tools Deliver a Deeper, More Effective Clean

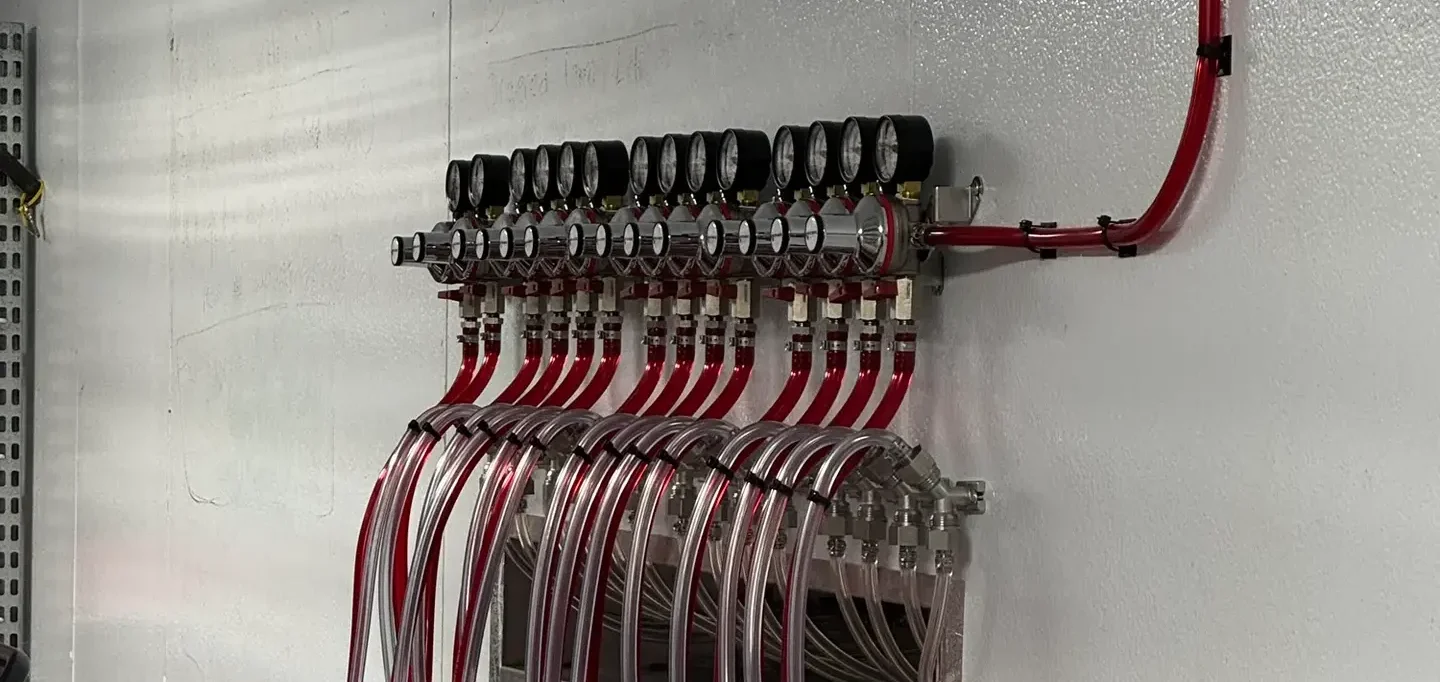

Professional technicians rely on high-powered equipment specifically designed for beer line maintenance.

- Pressurized circulation pumps ensure cleaning solutions travel through the entire system with enough force to break down stubborn buildup.

- Recirculation systems keep cleaners moving continuously, improving chemical contact and ensuring even the toughest beer stone and biofilm are fully removed.

- Specialized fittings and tools allow professionals to clean faucets, couplers, and connectors—areas often overlooked in DIY attempts.

This level of thoroughness simply cannot be achieved with standard at-home cleaning kits.

Expert Knowledge of Draft System Mechanics Prevents Costly Mistakes

Draft systems involve precise regulation of temperature, pressure, CO2 balance, and flow rate. Professionals undergo extensive training in draft system operations, allowing them to:

- Identify issues such as pressure imbalances, temperature inconsistencies, or early signs of mechanical wear.

- Notice small problems before they become expensive failures.

- Ensure cleaning agents are used at correct concentrations to avoid damaging seals, gaskets, or internal line components.

Their expertise ensures every part of the system functions properly after cleaning.

Consistent, Reliable Cleaning Schedules Keep Beer at Peak Quality

Professional services follow established industry schedules—typically every two weeks—to maintain optimal performance. They also:

- Track cleaning intervals so businesses never fall behind.

- Adjust cleaning frequency based on volume, beer types served, and seasonal fluctuations.

- Offer documentation to show breweries and distributors that lines meet industry-standard sanitation requirements.

This level of consistency guarantees fresh flavor and prevents the decline in beer quality that occurs when cleanings are irregular.

Specialized Chemical Solutions Ensure Maximum Sanitation

Professionals use industry-approved, commercial-grade solutions formulated to remove buildup safely and effectively. These include:

- Alkaline cleaners for removing organic matter like yeast and proteins.

- Acid-based cleaners for dissolving beer stone and mineral deposits.

- Sanitizers to eliminate harmful microorganisms and ensure a safe serving environment.

Correct chemical selection and application are essential to fully sanitize a draft system without leaving harmful residues.

Every Component Is Cleaned, Sanitized, and Reassembled Correctly

A proper commercial beer line cleaning extends far beyond the lines themselves. Technicians also clean and inspect:

- Faucets

- Couplers

- Shanks

- Beer towers

- Keg lines and connectors

- Drip trays and splash zones

This comprehensive approach ensures your entire draft system—not just the lines—is maintained for consistent, high-quality pours.

7 Common Risks of Inadequate DIY Cleaning

DIY beer line cleaning might seem appealing to save money, but it often leads to inconsistent results, incomplete sanitation, and long-term damage to the draft system. These risks can compromise beer quality, increase waste, and create costly repairs that far outweigh the cost of professional service.

1. Incomplete Removal of Beer Stone, Biofilm, and Organic Buildup

Most DIY cleaning tools and methods lack the circulation strength and chemical potency needed to break down hardened beer stone or deep-set biofilm.

Over time, these contaminants:

- Narrow the interior of beer lines, affecting flow and pressure

- Introduce off-flavors such as sour, buttery, or metallic notes

- Harbor bacteria, mold, and yeast that continue to spread throughout the system

Without commercial-grade agitation and chemical flushing, buildup remains—and grows back quickly.

2. Incorrect Chemical Ratios That Reduce Cleaning Effectiveness

Proper commercial beer line cleaning relies on precise chemical mixing. Using chemicals that are too weak will not sanitize the system, while solutions that are too strong can damage components.

Common DIY mistakes include:

- Over-diluting solutions, resulting in partial cleaning

- Using overly concentrated cleaners that corrode gaskets and seals

- Mixing incompatible products, which can cause harmful reactions

Professional technicians follow manufacturer guidelines to ensure safety and efficiency.

3. Insufficient Contact Time Leaves Contaminants Behind

Cleaning solutions must remain in the draft lines for a specific amount of time—usually a minimum of 10 minutes—to break down buildup effectively.

DIY cleaning often falls short because the solution:

- Isn’t circulated properly

- Isn’t left in the lines long enough

- Doesn’t maintain a stable temperature needed for full effectiveness

This leads to incomplete sanitation and rapid regrowth of contaminants.

4. Lack of pH Testing Allows Chemical Residue to Remain

Professional cleaning includes a critical step DIYers often skip: verifying the lines are free of chemical residue.

Without pH testing:

- Traces of cleaner may remain in the lines

- Beer can pick up chemical flavors or odors

- Customers may consume beer that’s unsafe or unpleasant

Ensuring proper pH balance is essential to serving safe, great-tasting beer.

5. Unintentional Damage to Draft System Components

Draft systems include sensitive parts such as seals, valves, couplers, and gaskets. Incorrect cleaning methods or harsh chemicals can:

- Crack or degrade rubber components

- Loosen fittings

- Corrode metal parts

- Cause leaks or pressure problems

Repairs can become expensive quickly, and the damage is often preventable with professional care.

6. Inconsistent Cleaning Schedules Create Flavor Problems and Costly Waste

DIY cleaning often lacks structure or regularity. Busy staff and management schedules make it easy to forget or delay cleanings, which can result in:

- Rapid flavor deterioration

- Increased foam and spillage

- Customer complaints

- More frequent system breakdowns

Professionals follow a strict, documented cleaning schedule to keep beer quality consistent.

7. Higher Long-Term Costs Compared to Professional Cleaning

Although DIY cleaning may appear to save money upfront, the long-term consequences often make it the more expensive option.

Hidden costs include:

- Wasted beer due to foaming and inconsistent pours

- More frequent equipment repairs or replacements

- Lost revenue from dissatisfied customers

- Time spent troubleshooting issues

Hiring experts ensures the entire system is cleaned thoroughly and correctly—protecting your investment and maintaining reliable performance.

Additional Best Practices to Maintain a Clean, Efficient Draft Beer System

- Clean faucets, couplers, and other components between line cleanings.

- Store kegs at proper temperatures to reduce spoilage.

- Monitor CO2 and pressure settings regularly.

- Rotate kegs properly and avoid extended stagnation.

- Train staff on basic draft care to maintain quality between professional cleanings.

Frequently Asked Questions | Commercial Beer Line Cleaning

How often should commercial beer line cleaning be performed?

Most draft systems require commercial beer line cleaning every two weeks to maintain fresh flavor and prevent buildup.

What happens if beer lines aren’t cleaned regularly?

Unclean lines lead to sour or metallic flavors, foaming issues, and reduced system efficiency. Regular cleaning prevents these problems.

Can business owners clean their own beer lines?

DIY methods rarely remove deeper buildup. Professional services ensure complete cleaning and protect the equipment.

Does cleaning the beer lines help reduce waste?

Yes. Clean lines improve flow stability and reduce foam, resulting in fewer wasted ounces per pour.

What cleaning chemicals are used for commercial beer line cleaning?

Technicians use approved alkaline or acid-based cleaners depending on buildup levels and system condition.

Protect Your Draft Quality With Professional Beer Line Cleaning in Putnam County

For businesses in Putnam County, maintaining a strong reputation means delivering consistently great beer. Routine commercial beer line cleaning is the foundation of reliable draft service, ensuring every pour is clean, crisp, and true to flavor.

Beer Line Cleaning USA provides comprehensive, professional cleaning that preserves product quality, protects equipment, and helps businesses operate at peak performance.

Ready to elevate your draft beer program? Contact Beer Line Cleaning USA to schedule expert commercial beer line cleaning services in Putnam County.

Clean beer lines ensure consistent flavor and protect the brewer’s intended taste.

Clean beer lines ensure consistent flavor and protect the brewer’s intended taste.