Dirty lines don’t just ruin flavor. They cost you money, cause waste, frustrate customers, and slowly damage your equipment. That’s why understanding how commercial beer line cleaning works (and how often you should do it) is essential for any beer-serving business in America, from bars and restaurants to breweries, event venues, and tap trucks.

Table of Contents

Key Takeaways

|

What Is Commercial Beer Line Cleaning?

Commercial beer line cleaning is the professional process of flushing, sanitizing, and restoring the draft lines that carry beer from the keg to the tap. Every time beer flows through those lines, tiny particles of yeast, sugar, bacteria, hops, and minerals cling to the inside.

Without regular commercial beer line cleaning, that buildup becomes a sticky layer of biofilm that contaminates every pour. Common draft system contaminants include lactic acid bacteria (Lactobacillus, Pediococcus), acetic acid bacteria (Acetobacter), and wild yeasts (Brettanomyces, Pichia).

If you’ve ever heard customers say their beer tastes “off,” too sour, too buttery, or strangely metallic, dirty lines were likely the cause.

Why Clean Beer Lines Matter for Every Beer Business

In hospitality and food-service, perception is everything—and clean lines are non-negotiable.

Your customers judge your beer by taste, not by how expensive the keg was or how new your tap system is. Clean lines ensure:

- Consistent flavor

- Less foam and fewer wasted pours

- A safer, sanitary system

- A professional, trustworthy reputation

What Happens When Beer Lines Aren’t Cleaned Regularly

Without routine commercial beer line cleaning, your system becomes a perfect breeding ground for:

- Biofilm made of bacteria and yeast

- Mold in couplers and faucets

- Beer stone, a hard mineral buildup

- Corrosion inside the system

How to Tell If Your Beer Lines Are Dirty

Excessive Foam or Flat Pours

Foam issues are often the first symptom of contamination. Dirty lines disrupt carbonation levels, causing unstable pours and cutting into your profit with every wasted pint.

Sour, Buttery, Metallic, or “Skunky” Flavors

Off-flavors almost always point to biofilm, bacteria, or yeast buildup. When customers complain about taste, it’s a strong sign your system needs immediate commercial beer line cleaning.

Cloudy or Hazy Appearance

Cloudiness can indicate yeast residue, sediment, or mold growth inside the lines—none of which should be anywhere near your beer.

Strange or Musty Odors

Beer should never smell “off.” Unpleasant odors often come from bacteria colonies or old beer stone breaking loose.

Slower or Inconsistent Flow Rate

Clogs, buildup, or partially blocked lines cause sluggish dispensing. If flow rate drops, a thorough cleaning is overdue.

Sticky Faucet Handles

Sticky or gummy handles are a sign of dried beer residue and poor sanitation. This usually means the interior of your lines is also compromised.

Increased Keg Waste or Bad Pours

Sudden spikes in waste—foamy pours, flat beer, or excess dumping—are usually caused by contamination or blockages.

How the Cleaning Process Works

1. Initial Disconnect

The technician safely shuts down the draft system and disconnects kegs, faucets, and couplers.

This step isolates the beer lines to ensure:

- No product contamination

- No pressure-related hazards

- Full access to each component requiring cleaning

2. Solution Mixing

A food-safe, industry-approved cleaning solution is mixed at the precise concentration needed to break down buildup.

This includes:

- Caustic or alkaline cleaners for yeast, sugar, and biofilm

- Acid-based cleaners for beer stone and mineral deposits

- Temperature-controlled water for maximum effectiveness

3. Circulate Cleaner

The cleaning solution is pumped through the beer lines using a professional circulation system.

This stage:

- Dislodges bacteria colonies

- Breaks apart biofilm

- Removes residue inside long or complex line runs

4. Soak

The solution is allowed to sit inside the lines for a measured contact time.

A proper soak helps:

- Dissolve stubborn residue

- Penetrate deep layers of biofilm

- Break down beer stone deposits

5. Drain

After soaking, the contaminated cleaning solution—along with all loosened debris—is flushed out of the lines.

This prevents:

- Chemical residue buildup

- Recontamination

- Flavors transferring back into fresh beer

6. Rinse

Clean water is flushed through the system multiple times until a neutral pH is confirmed.

A proper rinse:

- Ensures no cleaning agents remain

- Prepares the lines for safe beer contact

- Meets Brewers Association standards

7. Sanitize and Reassemble

Faucets, couplers, and connectors are individually scrubbed, sanitized, and reattached to the system.

The technician then:

- Performs a final system check

- Restores CO₂ or nitrogen pressure

- Ensures beer will flow cleanly and safely

How Often to Clean

Every Two Weeks

This is the nationwide industry standard recommended by the Brewers Association. Cleaning every 14 days helps:

- Prevent biofilm from attaching to the interior of the lines

- Maintain fresh, consistent beer flavor

- Reduce foaming and waste

- Extend the life of your draft equipment

Every Three Months

Quarterly deep cleanings go beyond routine sanitation. They typically include:

- Inspecting couplers, faucets, and gaskets

- Replacing worn seals

- Checking for early signs of corrosion or beer stone

- Ensuring system components operate safely under pressure

Annually

Once a year, your system benefits from a comprehensive evaluation, which may involve:

- Full line replacement if needed

- Pressure testing

- Thorough inspection of keg rooms and gas systems

- Replacement of aging components

As Needed

Certain circumstances call for additional commercial beer line cleaning beyond the regular schedule:

- Busy seasons or high-volume holidays

- Beer festivals or special events

- Switching between drastically different beer styles

- After long system downtime

- When flavor or flow issues arise unexpectedly

How Long Do You Leave Beer Line Cleaner in the Lines?

During professional commercial beer line cleaning, the cleaning solution typically remains in the lines for 10–15 minutes, depending on buildup and system condition. Proper contact time is critical for effective sanitation.

A correct soak ensures:

- Complete breakdown of biofilm, yeast, and sugar residue

- Effective removal of mold or early beer stone

- Safe sanitation without damaging line materials

Leaving the cleaner in too briefly won’t sanitize the system. Leaving it too long can cause chemical residue or unnecessary wear. This is why most businesses rely on trained technicians—they know exactly how long each step should take for optimal results.

How Long Does Beer Line Cleaning Take?

A standard commercial beer line cleaning appointment takes 30–60 minutes for most bars, restaurants, and taprooms. The total time depends on:

- The number of tap lines

- The length of the beer lines

- System layout and accessibility

- Whether the session includes deep cleaning or component replacement

Multi-tap systems, breweries, or venues with extended line runs may require additional time, but the downtime is still minimal—especially compared to the cost of serving bad beer.

How Much Does It Cost to Have Beer Lines Cleaned?

The cost of commercial beer line cleaning can vary depending on your system and cleaning frequency. Most providers structure pricing around:

- Per-visit rates for routine two-week cleanings

- Higher costs for deep cleanings, neglected lines, or systems with unusual length or complexity

- Discounted rates for recurring service contracts or multi-line accounts

Routine cleaning is always the most economical choice. It helps businesses save money by:

- Reducing waste caused by foamy or off-flavor pours

- Extending equipment life

- Preventing expensive repairs from corrosion or beer stone buildup

- Maintaining consistent product quality that wins customer loyalty

In short, regular commercial beer line cleaning is both a maintenance expense and a profit-protecting investment for any business that serves beer.

Choosing a Reliable Partner for Commercial Beer Line Cleaning

Proven Experience

Look for technicians with hands-on experience across bars, restaurants, breweries, long-draw systems, and high-volume environments. Experienced pros know how to diagnose issues, prevent contamination, and keep your draft system performing at its best.

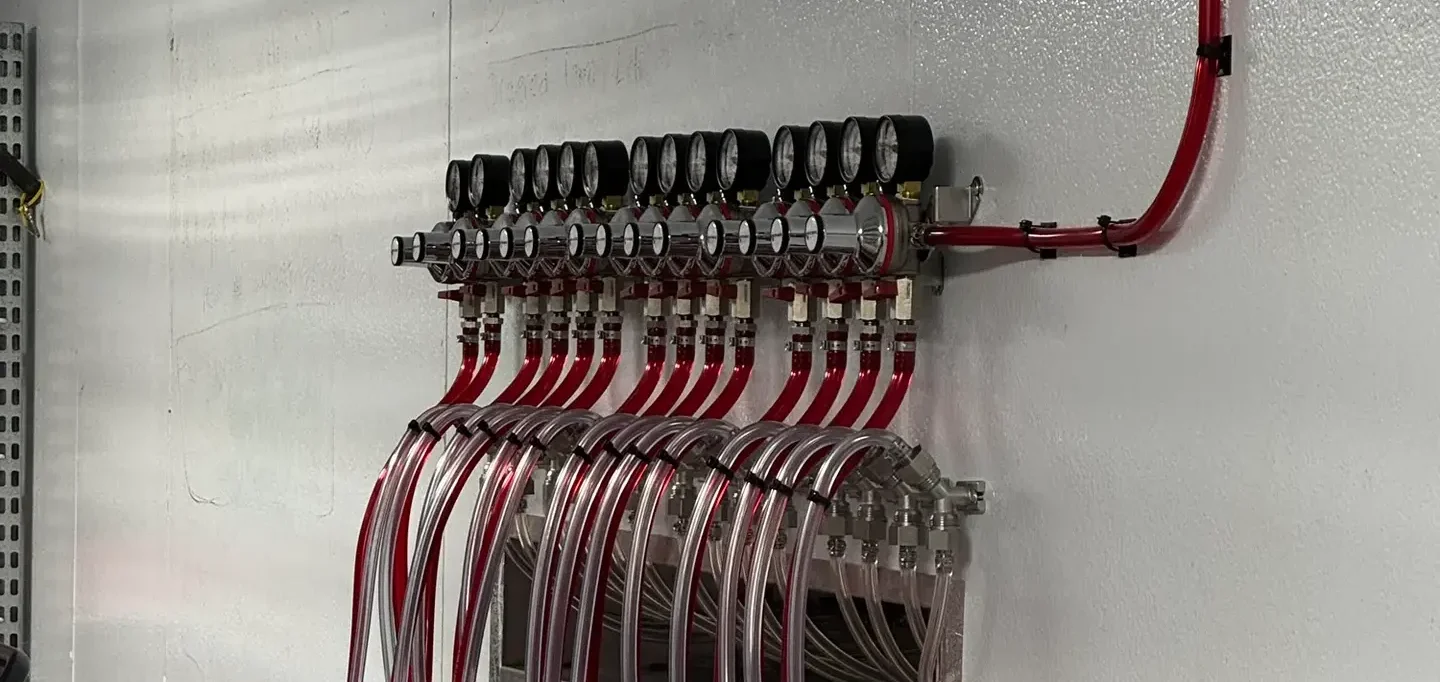

Commercial-Grade Equipment

Professional pumps, circulation systems, pH testing tools, and industry-approved chemicals ensure the deepest and safest clean. Avoid companies that rely on outdated tools or basic static cleaning methods.

Compliance With Industry Guidelines

A reliable provider follows Brewers Association standards, correct chemical contact times, and safety protocols. This ensures your commercial beer line cleaning meets the same quality benchmarks used in professional breweries.

Transparent Pricing

Look for clear pricing structures for routine cleanings, deep cleanings, long-line runs, and service contracts. No hidden fees or vague estimates.

Consistent, Dependable Scheduling

Your beer quality depends on sticking to a strict cleaning cycle. Choose a company that shows up on time, keeps your two-week rotation on track, and communicates clearly.

Knowledge of Multiple Draft Systems

From kegerators to long-draw glycol systems, your provider should understand the unique needs and cleaning requirements of your setup.

Technician Training & Certifications

Ask whether the company invests in ongoing training. Certified or brewery-trained technicians ensure your system is handled correctly.

Use of Safe, Approved Cleaning Agents

The company should use only food-safe, industry-approved solutions tailored for commercial beer line cleaning—not generic cleaners.

Detailed Documentation & Reporting

Top providers offer cleaning logs, pH test results, and notes on equipment condition. This gives you a clear record of maintenance and helps catch issues early.

Emergency Support or Short-Notice Availability

Beer festivals, special events, and unexpected system problems may require urgent cleaning. A responsive partner makes a big difference when your business is on the line.

Frequently Asked Questions

Can commercial beer line cleaning help reduce beer waste?

Yes. Professional commercial beer line cleaning improves pour stability, reduces foam, and prevents off-flavors—directly lowering the amount of beer your staff has to dump or remake.

Does commercial beer line cleaning work with all types of draft systems?

Absolutely. Whether you use short-draw, long-draw, direct-draw, glycol-chilled, or high-volume systems, professional commercial beer line cleaning can be customized to fit your exact setup.

Can dirty beer lines affect the alcohol content of the beer?

Not the actual alcohol content—but contaminated lines can alter taste, aroma, and carbonation. Routine commercial beer line cleaning preserves the beer’s intended quality.

Do different beer styles require more frequent cleaning?

Yes. Hoppy beers, sours, fruit beers, and unfiltered styles leave more residue. These products often benefit from more frequent commercial beer line cleaning to prevent buildup.

Can commercial beer line cleaning improve customer reviews?

Definitely. Clean lines mean better-tasting beer, fewer complaints, and more consistent pours—all of which contribute to stronger customer satisfaction and better online ratings.

Keep Your Draft System Clean, Safe, and Pouring Profitably

Commercial beer line cleaning is one of the simplest, smartest investments you can make for your business. It protects your product, your customers, and your bottom line—and the difference is something your customers taste immediately.

If you want fresher beer, smoother pours, and a healthier draft system, Beer Line Cleaning USA is your go-to expert in Putnam County.

Dirty beer lines quickly ruin flavor, waste product, and damage your draft equipment.

Dirty beer lines quickly ruin flavor, waste product, and damage your draft equipment.