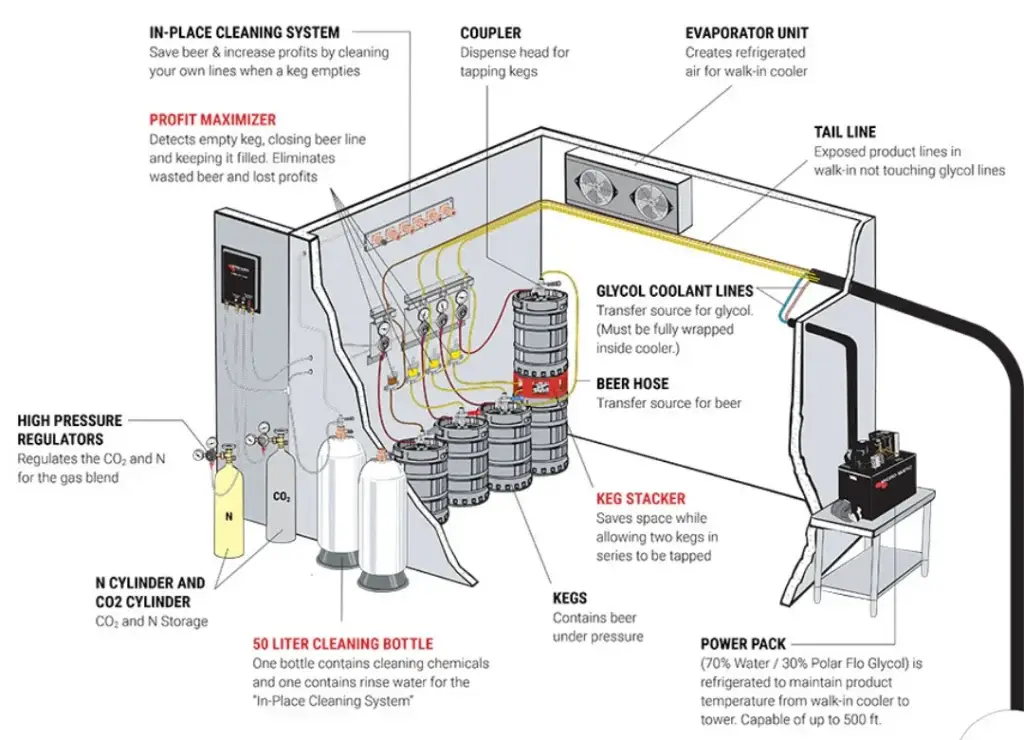

Beer stone, sugar buildup, and microbial growth corrode stainless steel, clog faucets, and permanently bond inside beer lines when left too long. Once this happens, even the strongest cleaning methods can’t remove them. This buildup ruins FOB function and gums up couplers, causing leaks and costly failures. Routine professional cleanings prevent irreversible damage and protect your investment in taps and lines.