Table of Contents

Key Takeaways✔ Keg-to-tap distance determines system type, with runs over 25 feet typically requiring glycol cooling for consistent temperature and pours. ✔ Direct-draw systems work best for shorter distances and fewer taps, offering a simpler and more budget-friendly setup. ✔ Long-draw systems are ideal for higher volume and more bar taps, supporting multiple beers with stronger temperature control. ✔ Space planning for keg storage, line routing, and refrigeration directly affects service efficiency and long-term system performance. ✔ Professional beer tap installation and routine maintenance help reduce foam, minimize waste, and protect beer quality from keg to glass. |

Choosing the right draft beer system depends on keg-to-tap distance, space, budget, and volume, primarily deciding between affordable, simple Direct-Draw (short distances, fewer taps) or more complex, costly Long-Draw (over 25 ft, multiple beers with glycol cooling) for temperature control, with factors like kegerators for small setups and walk-in cooler options for efficient, multi-tap commercial bars guiding your choice for perfect pours and efficient service.

Understanding Draft Beer Systems for Commercial Use

A draft beer system is more than a faucet and a keg. In commercial settings, draft beer installation must be properly balanced to protect temperature, carbonation, and flavor, since small setup errors can cause foam, flat pours, and inconsistency.

Unlike a simple home beer tap, commercial setups handle higher volume and multiple beer styles. A professional beer tap system includes refrigeration, lines, gas, faucets, and often cooling support, all working together for reliable service.

For bars, restaurants, and breweries, the tap system affects both customer experience and operational speed, making the right setup from the start essential.

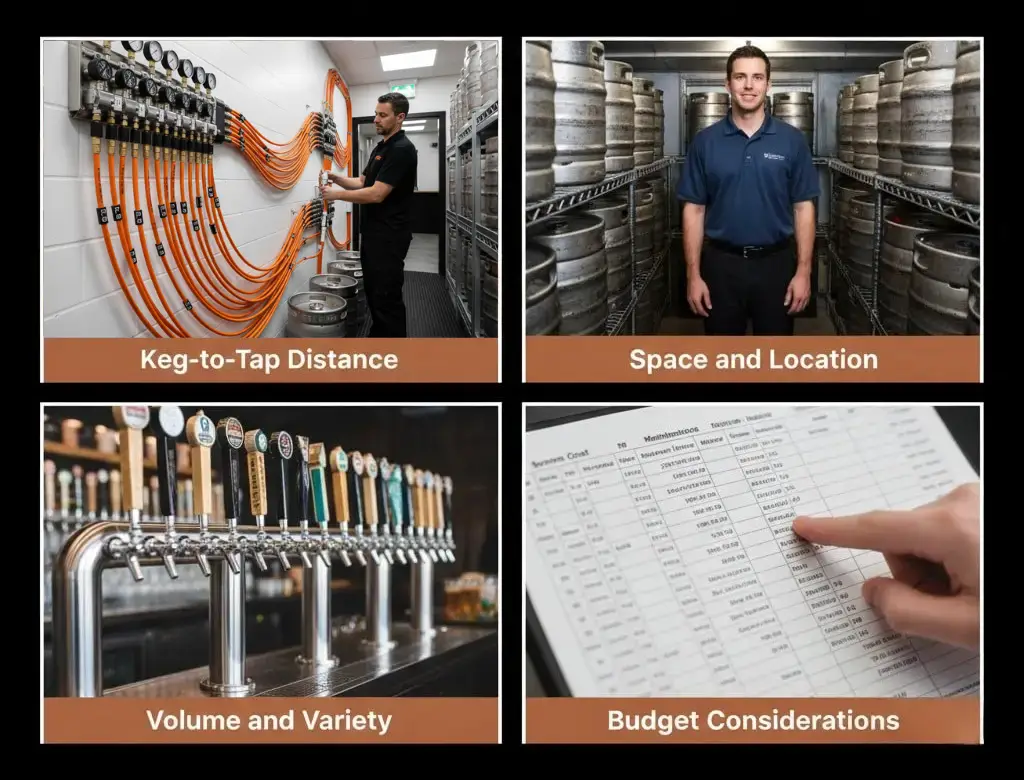

4 Key Factors in Choosing the Right Draft Beer System for Your Business

Selecting the proper draft beer system is not about choosing the most expensive option. It is about matching the system design to how the business operates day to day. Factors like distance, layout, volume, and budget determine whether a simple or complex solution makes sense.

✔ Keg-to-Tap Distance

Keg-to-tap distance is the most critical factor in any draft beer installation. When the distance between the keg and the faucet exceeds 25 feet, maintaining proper beer temperature becomes difficult without specialized cooling. Longer runs require a glycol-cooled tap system to prevent warm beer and excessive foam.

Short distances under 25 feet allow for simpler designs where kegs are stored close to the bar taps. These setups reduce complexity and cost while still delivering excellent results when designed correctly.

✔ Space and Location

Every business has unique space constraints. Some venues have room for a walk-in cooler, while others rely on under-bar or back-bar refrigeration. Draft beer installation must account for where kegs, lines, and cooling equipment will physically fit.

Under-bar systems provide easy access for bartenders but limit capacity. Walk-in coolers allow for higher volume and better organization. The chosen beer tap system should support efficient workflow without disrupting service.

✔ Volume and Variety

High-volume venues with multiple bar taps require systems built for consistency and speed. Serving ten or more beers on tap places different demands on the equipment than serving two or three core offerings.

A business offering a wide variety of beers benefits from a long-draw tap system that maintains temperature across multiple lines. Lower-volume locations often perform better with direct-draw systems that keep beer fresh without overengineering.

✔ Budget Considerations

Budget plays a significant role in draft beer installation decisions. Direct-draw systems cost less upfront and are easier to maintain. Long-draw systems cost more but provide superior temperature control and scalability.

While upfront cost matters, long-term performance and reduced beer waste often justify higher initial investment. A well-designed beer tap installation pays for itself through consistent quality and fewer operational issues.

Types of Draft Beer Systems Explained.

Understanding the primary system types helps business owners make informed decisions that align with operational needs

✔ Direct-Draw Draft Beer Systems

A direct-draw system stores kegs close to the bar taps, typically in a refrigerated cabinet or cooler directly beneath or behind the bar. Beer travels a short distance before reaching the faucet. This type of tap system works best for smaller bars, cafes, and restaurants with limited space and lower tap counts. It is also common in tasting rooms and boutique venues.✔ Long-Draw (Glycol-Cooled) Draft Beer Systems

Long-draw systems use a glycol power pack to circulate chilled coolant alongside beer lines, keeping beer cold over extended distances. This design is essential when keg storage is remote from the bar taps. Large venues, stadiums, hotels, and high-volume bars rely on long-draw systems to maintain consistency across many taps. A properly installed draft beer installation of this type ensures every pour tastes as intended.✔ Kegerators

Kegerators are self-contained refrigeration units that combine cooling and dispensing in one compact system. While commonly associated with residential use or a discreet home beer tap, they also serve small commercial needs. They work well in offices, private clubs, or venues serving limited draft options. Kegerators are a simplified beer tap system that prioritizes convenience over scalability.Installation Considerations for Commercial Draft Beer Systems

Designing the system is only part of the process. Installation choices directly affect performance and longevity.

✔ Walk-In Cooler Installations

Walk-in coolers are ideal for high-volume draft beer installation. Beer lines can run directly from the cooler to the bar taps, reducing temperature fluctuation. This setup improves efficiency and simplifies keg storage.

Many walk-in cooler systems function as short-draw or modified direct-draw systems depending on distance. They are common in full-service bars and restaurants with strong draft programs.

✔ Under-Bar and Back-Bar Installations

Under-bar systems keep kegs close to the serving area, making them ideal for smaller operations. Back-bar refrigeration offers visibility and convenience while supporting a limited number of taps.

These configurations require careful beer tap installation to ensure proper airflow and easy access for maintenance.

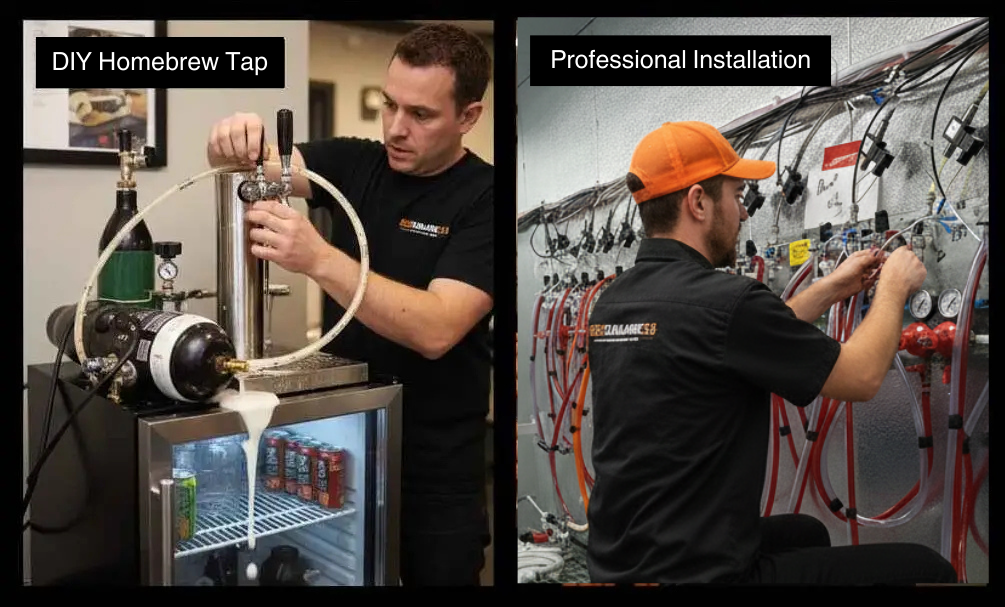

✔ Professional Draft Beer Installation

Professional installation is strongly recommended for any commercial tap system. Experienced technicians balance line length, gas pressure, and cooling requirements to match beer styles and system design.

Improper installation often leads to foam, waste, and inconsistent pours. Professional draft beer installation protects equipment investment and ensures compliance with industry standards.

What Is the Typical Cost of Installing a Draft Beer System?

Draft beer installation costs vary by system type and size. Direct-draw setups often start in the low thousands, while long-draw systems can reach tens of thousands, depending on bar taps, keg-to-tap distance, refrigeration needs, and labor.

As the hospitality sector expands, especially in emerging economies, demand for professional draft systems continues to shape the market. A well-designed beer tap installation can reduce waste and improve service efficiency over time.

Is It Possible to Build a Draft Beer System Yourself?

Building a draft beer system independently is possible for small-scale or personal use. Many enthusiasts successfully tap a keg at home using basic components. However, commercial environments present additional challenges.

DIY installations often struggle with proper line balancing, temperature control, and regulatory compliance. In a business setting, improper beer tap installation can lead to product loss and health code issues.

For commercial operations, professional installation is the safest and most reliable choice.

What Is the Ideal Flow Rate for Pouring Draft Beer?

Flow rate refers to how quickly beer moves from the faucet into the glass. The ideal rate typically falls between one and two ounces per second, depending on the beer style and system design.

Proper flow rate ensures minimal foam and consistent carbonation. Achieving this balance requires correct line length, diameter, and gas pressure within the tap system.

Experienced installers adjust flow rate during draft beer installation to match real-world conditions. This attention to detail separates average systems from exceptional ones.

Frequently Asked Questions

How often should draft beer lines be cleaned?

Draft beer lines should be cleaned regularly to maintain flavor quality and prevent buildup that affects pours. Most commercial systems require cleaning every two weeks, while high-volume or heavily used systems may need more frequent service. Skipping cleanings can cause off-flavors and reduce system efficiency. Consistent maintenance also extends the lifespan of the tap system.

Does the type of beer affect draft system setup?

Different beer styles place different demands on a draft system. Carbonation levels, serving temperature, and viscosity can all influence line length and pressure requirements. A properly designed system accounts for these variations to ensure consistent pours. Ignoring beer style differences often leads to foam or flat beer.

Can a draft beer system impact beer taste?

Yes, draft system design has a direct effect on taste. Temperature control, clean lines, and balanced pressure all help preserve the intended flavor profile. Poorly designed or neglected systems can introduce oxidation or contamination. Consistent system performance protects beer quality from keg to glass.

Are draft beer systems energy efficient?

Energy efficiency depends on system design and equipment quality. Modern refrigeration and glycol systems are more efficient than older setups. Proper insulation and routine maintenance also reduce energy consumption. Efficient systems lower operating costs over time.

What maintenance tasks are commonly overlooked?

Routine inspections of seals, faucets, and gas connections are often overlooked. Small leaks or worn components can lead to waste and inconsistent pours. Regular checkups help identify issues before they become costly problems. Preventive maintenance improves reliability.

Schedule Professional Draft Beer Service in Putnam County

Reliable draft systems depend on expert care, proper maintenance, and experienced service providers who understand commercial beer equipment. Beer Line Cleaning USA delivers professional draft beer support for bars, restaurants, and hospitality venues throughout Putnam County, ensuring clean lines, consistent pours, and compliant systems.

Contact Beer Line Cleaning USA today to schedule service and keep draft systems performing at their best!